Woodpecker Grid Hardening

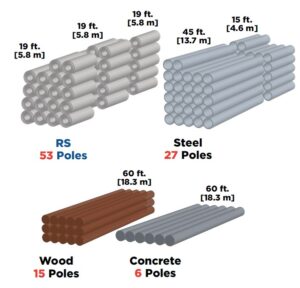

THREAT: WOODPECKERS APPLICATION: ALL WOOD POLES IN THE WOODPECKERS’ HABITAT LOCATION: ONTARIO, CANADA OTHER CONSIDERATIONS: REMOTE ACCESS Ten ounces of relentless destruction. Never has there been something so small that is solely responsible for such tenacious annihilation of wood poles. The theory largely prescribed to in the utility industry that attempts to explain the woodpeckers’ attraction to utility poles is that wind on the conductors induces a subtle vibration on the pole. The woodpecker, ever the efficient hunter, then believes that there are carpenter ants or wood-boring beetle larvae – its main food – in the wood pole and it will stop at nothing to get that food. It is for this reason that remediation methods like fillers and wraps will never stop the resolute conviction of the pileated woodpecker. Those products are challenging and costly to install on wood poles, and only increase operation and maintenance expenses, and yet the woodpeckers relentlessly keep coming back over and over again. Once the damage is done, the wood pole is structurally compromised and the probability that the pole will fail in a high load event like a wind gust or an ice storm is dramatically increased. No wrap or pole filler will reinstate the structural capacity that is lost to a woodpecker hole. Break the cycle. RS composite poles eliminate the woodpecker threat. It’s that simple. “A woodpecker can destroy a wood pole in one day. Put in a composite pole and your problem is solved.” — Dave Whittier, Hydro One