Composite Solutions You Can Trust

Our Pole Support Systems and Accessories streamline installation, enhance safety, and fortify your grid against the challenges that threaten traditional materials. Whether you’re safeguarding infrastructure against wildfire damage or enabling efficient installation in remote or tight spaces, our innovative support solutions are engineered for exceptional performance.

01

Fire Shield

Faced with increasing wildfire size, intensity and frequency, the utility industry is actively seeking a sustainable grid hardening solution for wildfire mitigation.

EXPOSURE DURATION: 3 MIN

TOTAL HEAT FLUX: 16,540 kW-s/m²

PEAK TEMPERATURE: 2,332°F [1,278°C]

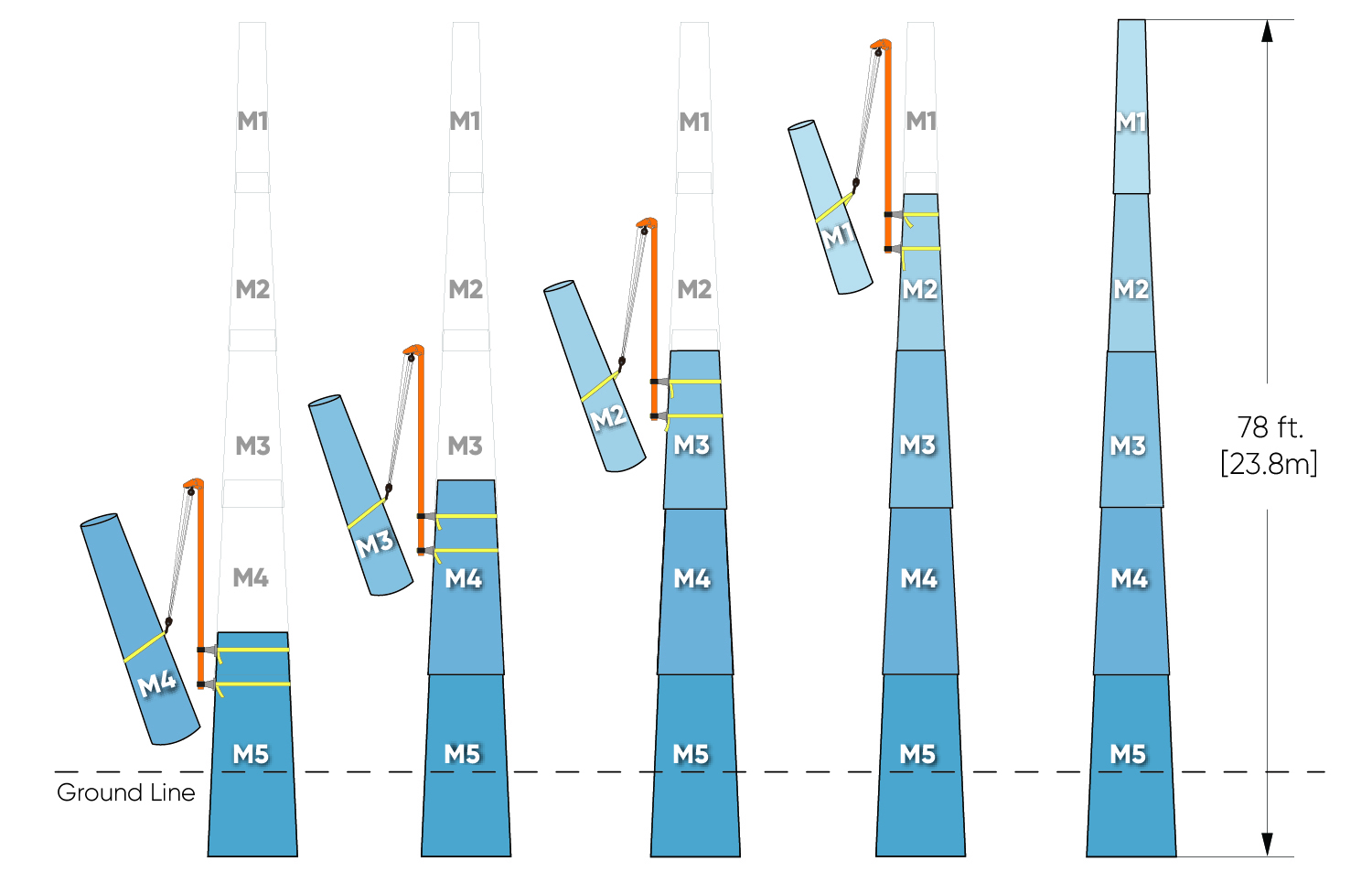

Gin Pole

The distribution grid has millions of poles located in challenging areas. Some of these locations could even be in your own backyard as decades of urban intensification have built up around the grid

hardware

Hardware connections can be an overlooked component in overhead lines, however, they provide a critical function. Every connection to a pole requires hardware and, like wood, steel and concrete poles, there are some considerations to be aware of.